-

Out of stock

PAI DR-9 Solder Dross Reducer was developed by PAIPL (Persang Alloy Industries Pvt. Ltd.) to counter solder oxides and is being applied to remove solder oxides in wave soldering process and other processes where molten solder is used. DR-9 is hazardous and precautions to be taken in storage, handling and processing. DR-9 effectively separates metal and metal oxides from solder dross. However, DR-9 does not play any role in controlling the formation of dross which is proportional to associated aspects of soldering process. Weight : 100gm

PAI DR-9 Solder Dross Reducer was developed by PAIPL (Persang Alloy Industries Pvt. Ltd.) to counter solder oxides and is being applied to remove solder oxides in wave soldering process and other processes where molten solder is used. DR-9 is hazardous and precautions to be taken in storage, handling and processing. DR-9 effectively separates metal and metal oxides from solder dross. However, DR-9 does not play any role in controlling the formation of dross which is proportional to associated aspects of soldering process. Weight : 100gm -

Out of stock

PAI SP-610 RoHS compliance solder wires are being formulated with high virgin raw metals processed in state-of-the-art Vaccualloy Technology that brings world class quality along. Here, oxygen interaction with alloy is nil and thus, dross formulation is reduced at PCB assembly process. Also an increased flow rate & reduced impurities found. PAI SP-610 alloy is compatible for a typical range of flux application formulas used in Electronics Industry today.

Download - Technical Data Sheet

-

Out of stock

PAI Sn99.3Cu0.7 RoHS compliance solder wires are being formulated with virgin raw metals processed in state-of-the-art Vaccualloy Technology that brings world class quality along. Here, oxygen interaction with alloy is nil and thus, dross formulation is reduced at PCB assembly process. Also an increased flow rate & reduced impurities found. PAI Sn99.3Cu0.7 alloy is compatible for a typical range of flux application formulas used in Electronics Industry today.

PAI Sn99.3Cu0.7 RoHS compliance solder wires are being formulated with virgin raw metals processed in state-of-the-art Vaccualloy Technology that brings world class quality along. Here, oxygen interaction with alloy is nil and thus, dross formulation is reduced at PCB assembly process. Also an increased flow rate & reduced impurities found. PAI Sn99.3Cu0.7 alloy is compatible for a typical range of flux application formulas used in Electronics Industry today.Download - Technical Data Sheet

-

Out of stock

High purity Alloy that is composed of 63% Tin and 37% Lead from Virgin Metals. Applies at Hand or Feed Soldering Process in Electronic & Electrical Assemblies. Non-Corrosive and No Impact of Residues form at Post Soldering which means of passes in Pin Probe & Flying Probe Tests for No Clean Wires. If requires, Residues shall clean with appropriate Liquid Application. Précised amount of Flux cored from state-of the-art-Technology Process.

High purity Alloy that is composed of 63% Tin and 37% Lead from Virgin Metals. Applies at Hand or Feed Soldering Process in Electronic & Electrical Assemblies. Non-Corrosive and No Impact of Residues form at Post Soldering which means of passes in Pin Probe & Flying Probe Tests for No Clean Wires. If requires, Residues shall clean with appropriate Liquid Application. Précised amount of Flux cored from state-of the-art-Technology Process.Download - Technical Data Sheet

-

Out of stock

High purity alloy that is composed of 60% Tin and 40% Lead from virgin metals. Applies at hand or feed soldering processes in Electronics & Electrical assemblies. Non-corrosive and no impact of flux residues forming at post soldering which means of passing in pin probe & flying probe tests for No Clean solder wires. If required, flux residues shall be cleaned with appropriate liquid application. Précised amount of flux cored from state-of the-art-technology manufacturing process.

Download - Technical Data Sheet

SPECIAL OFFER

BUY 6-10 KGs & Avail Flast 5% Discount

-

Out of stock

PAI SnAg0.3Cu0.7+Ni+Ge RoHS compliance solder wires are being formulated with high virgin raw metals processed in state-of-the-art Vaccualloy Technology that brings world class quality along. Here, oxygen interaction with alloy is nil and thus, dross formulation is reduced at PCB assembly process. Also an increased flow rate & reduced impurities found. PAI SnAg0.3Cu0.7+Ni+Ge alloy are compatible for a typical range of flux application formulas used in Electronics Industry today.

Download - Technical Data Sheet

-

Out of stock

PAI tin/lead no-clean solder pastes are made from a special formulation of highest purity ingredients to ensure the process consistency of today's demanding ultra-fine-pitch challenges. Our formulation offers a wide processing window and excellent shelf life, with full wetting and clean-ability features to prolong stencil life. SH6309 is a Sn63/Pb37 alloy with Type 3 particle size (+45 µm 1% less, -20 µm 10% less) and no-clean ROL0 flux. It comes packaged in a 500-gram jar.

PAI tin/lead no-clean solder pastes are made from a special formulation of highest purity ingredients to ensure the process consistency of today's demanding ultra-fine-pitch challenges. Our formulation offers a wide processing window and excellent shelf life, with full wetting and clean-ability features to prolong stencil life. SH6309 is a Sn63/Pb37 alloy with Type 3 particle size (+45 µm 1% less, -20 µm 10% less) and no-clean ROL0 flux. It comes packaged in a 500-gram jar.- High print speed (0-120 mm/sec)

- Excellent wettability

- Reflow with or without nitrogen

- Low void

- Over 8 hours stencil life

- Extended tack time > 12 hours

-

Out of stock

SH-6209-4 PAI tin/lead/silver no-clean solder pastes are made from a special formulation of highest purity ingredients to ensure the process consistency of today’s demanding ultra-fine-pitch challenges. Our formulation offers a wide processing window and excellent shelf life, with full wetting and clean-ability features to prolong stencil life. SH-6209-4 is a Sn62.8 / Pb36.8 / Ag0.4 alloy with Type 3 & Type 4 and no-clean ROL0 flux. It comes packaged in a 500-gram & 250-grams jar.

SH-6209-4 PAI tin/lead/silver no-clean solder pastes are made from a special formulation of highest purity ingredients to ensure the process consistency of today’s demanding ultra-fine-pitch challenges. Our formulation offers a wide processing window and excellent shelf life, with full wetting and clean-ability features to prolong stencil life. SH-6209-4 is a Sn62.8 / Pb36.8 / Ag0.4 alloy with Type 3 & Type 4 and no-clean ROL0 flux. It comes packaged in a 500-gram & 250-grams jar.- High print speed (0-120 mm/sec)

- Excellent wettability

- Reflow with or without nitrogen

- Low void

- Over 8 hours stencil life

- Extended tack time > 12 hours

-

Out of stock

SH-6209 PAI tin/lead/silver no-clean solder pastes are made from a special formulation of highest purity ingredients to ensure the process consistency of today’s demanding ultra-fine-pitch challenges. Our formulation offers a wide processing window and excellent shelf life, with full wetting and clean-ability features to prolong stencil life. SH-6209 is a Sn62Ag2Pb36 alloy with Type 3 & Type 4 and no-clean ROL0 flux. It comes packaged in a 500-gram & 250-grams jar.

SH-6209 PAI tin/lead/silver no-clean solder pastes are made from a special formulation of highest purity ingredients to ensure the process consistency of today’s demanding ultra-fine-pitch challenges. Our formulation offers a wide processing window and excellent shelf life, with full wetting and clean-ability features to prolong stencil life. SH-6209 is a Sn62Ag2Pb36 alloy with Type 3 & Type 4 and no-clean ROL0 flux. It comes packaged in a 500-gram & 250-grams jar.- High print speed (0-120 mm/sec)

- Excellent wettability

- Reflow with or without nitrogen

- Low void

- Over 8 hours stencil life

- Extended tack time > 12 hours

-

Out of stock

PART NO: PF610

The higher processing temperatures required for lead-free soldering make unprecedented demands on solder pastes. In addition to consistent printing and reflow requirements, there is a need for higher repeatability in high mix, high-yield lines. All these and other Pb-free challenges are met with consistency in SMTSolderPaste.com's lead-free pastes. Processable by air or nitrogen reflow, they offer the advantages of excellent wetting characteristics and long shelf life. PF610 is an Sn/Ag3.0/Cu0.5/Ni+Ge alloy with Type 3 & Type 4 and no-clean ROL0 flux. It comes packaged in a 500-gram & 250-grams jar.Download - Technical Data Sheet- Pb < 1000 ppm, Cd < 20 ppm

- High print speed: 0-120 mm/sec

- Over 8 hours stencil life

- Extended tack time > 12 hours

- Excellent wettability

- Low void

-

Out of stock

Lead-Free No Clean Solder Paste PART NO: PF609 PF609 is a low-cost, lead-free halogen-free solder paste that offers the performance of tin-lead and high-silver lead-free solder pastes. PF609 is an Sn/Ag0.3/Cu0.7 alloy with Type 3 particle size (+45 µm 1% less, -20 µm 10% less) and Type 4 particle size (+38 µm 1% less, -20 µm 10% less) and no-clean ROL0 flux. It comes packaged in a 500-gram & 250-grams jar.

Lead-Free No Clean Solder Paste PART NO: PF609 PF609 is a low-cost, lead-free halogen-free solder paste that offers the performance of tin-lead and high-silver lead-free solder pastes. PF609 is an Sn/Ag0.3/Cu0.7 alloy with Type 3 particle size (+45 µm 1% less, -20 µm 10% less) and Type 4 particle size (+38 µm 1% less, -20 µm 10% less) and no-clean ROL0 flux. It comes packaged in a 500-gram & 250-grams jar.- Pb < 1000 ppm, Cd < 20 ppm

- High print speed: 0-120 mm/sec

- Over 8 hours stencil life

- Extended tack time > 12 hours

- Excellent wettability

- Low void

-

Out of stock

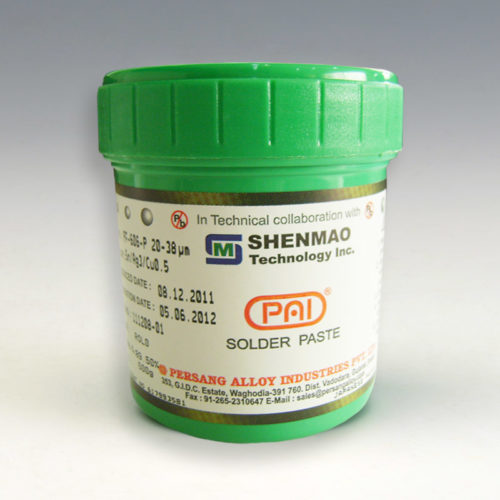

Lead-Free No Clean Solder Paste PART NO: PF606 The higher processing temperatures required for lead-free soldering make unprecedented demands on solder pastes. In addition to consistent printing and reflow requirements, there is a need for higher repeatability in high mix, high-yield lines. All these and other Pb-free challenges are met with consistency in PAI's lead-free pastes. Processable by air or nitrogen reflow, they offer the advantages of excellent wetting characteristics and long shelf life. PF606 is an Sn/Ag3.0/Cu0.5 alloy with Type 3 particle size (+45 µm 1% less, -20 µm 10% less) and Type 4 particle size (+38 µm 1% less, -20 µm 10% less) and no-clean ROL0 flux. It comes packaged in a 500-gram & 250-grams jar.

Lead-Free No Clean Solder Paste PART NO: PF606 The higher processing temperatures required for lead-free soldering make unprecedented demands on solder pastes. In addition to consistent printing and reflow requirements, there is a need for higher repeatability in high mix, high-yield lines. All these and other Pb-free challenges are met with consistency in PAI's lead-free pastes. Processable by air or nitrogen reflow, they offer the advantages of excellent wetting characteristics and long shelf life. PF606 is an Sn/Ag3.0/Cu0.5 alloy with Type 3 particle size (+45 µm 1% less, -20 µm 10% less) and Type 4 particle size (+38 µm 1% less, -20 µm 10% less) and no-clean ROL0 flux. It comes packaged in a 500-gram & 250-grams jar.- Pb < 1000 ppm, Cd < 20 ppm

- High print speed: 0-120 mm/sec

- Over 8 hours stencil life

- Extended tack time > 12 hours

- Excellent wettability

- Low void